Fab-Pak Options

Cell Controllers

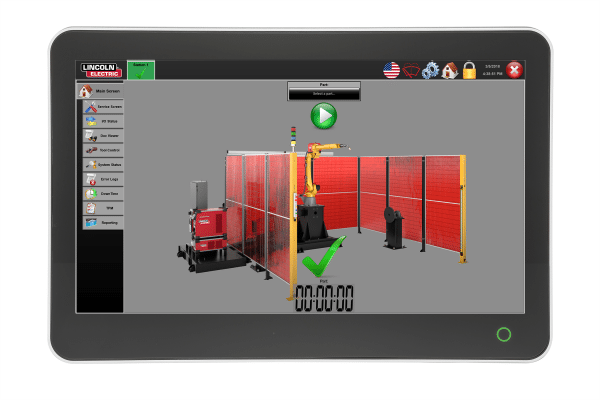

FAB-PAK CELL CONTROL

Fab-Pak® Cell Control is an easy-to-use, entry level, graphical user interface. The Fab-Pak cell control provides the operator of the Fab-Pak System control of normal production functions, robotic arc welding cell operation, and the welding process.

Fab-Pak Cell Control is available only on Fab-Pak pre-engineered welding systems.

Learn More

PLUS CELL CONTROL

Plus Cell Control is an easy-to-use, graphical user interface. The Plus Cell Control is intuitive, straightforward and provides the operator with the ability to control normal production functions, robotic arc welding cell operation, and the welding process. With Plus Cell Control, part production reports are included to help pinpoint areas of opportunity.

The Plus Cell Control provides a 21′ inch display with multi-touch capabilities.

Learn More

PREMIUM CELL CONTROL

Premium Cell Control is an easy-to-use, graphical user interface. The Premium Cell Control is intuitive, straightforward and provides the operator with the ability to control normal production functions, robotic arc welding cell operation, and the welding process. With Premium Cell Control, several reports are included to help provide production insights and to help ensure proper maintenance.

The Premium Cell Control provides a 21′ inch display with multi-touch capabilities.

Learn More

Process Equipment

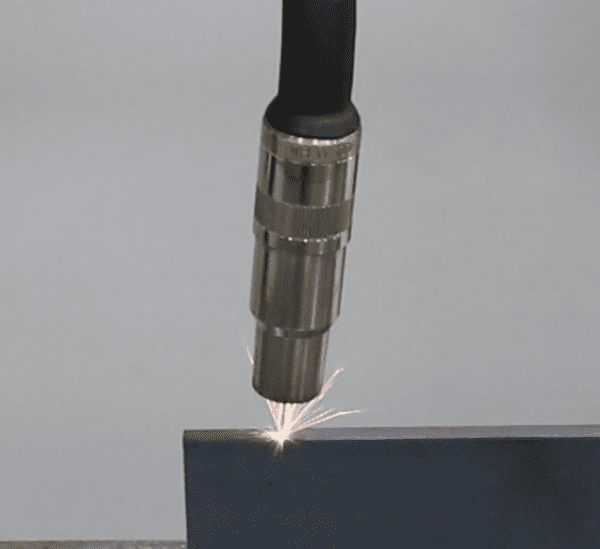

AUTODRIVE® S WIRE FEEDER

AutoDrive S employs touch-retract starting technology, a system that touches the wire to the work, senses the touch and retracts the wire, initiating the arc at a lower current. The softer start minimizes spatter or eliminates it altogether, and extends the life of the consumable. This reduces operating costs over the long term, and when there is little or no spatter to remove after the weld, up time and productivity improve dramatically.

MAGNUM PRO WATER-COOLED ROBOTIC TORCH

- Withstands High Duty Cycle Applications – Compared to traditional air-cooled torches, the Magnum® PRO Water-Cooled Robotic Torch can run at 100% duty cycle at 525A with 90/10 mixed gas.

- Extended Expendable Life – Conduction and convection cooling near the end of the torch keeps expendables cool. This expands the life of the expendables, increases the amount of arc-on time, and lowers replacement parts costs.

- TCP Repeatability – The gun tubes are designed with a robust inner and outer sheath that minimize damage upon crashing and improve TCP repeatability.

- Minimized Spatter Adhesion – The unique design of the gun tubes cools both the inner and outer sheath of material. This allows the outside of the gun tubes to remain cool, which minimizes the amount of spatter that adheres to the gun tubes.

- Ease of Installation – Floating fittings in the gun tubes allow for an easy installation that prevents water from leaking out of the torch. Additionally, visible hash marks simplify installation and make set up easy.

AUTODRIVE® SA ALUMINUM SERVOTORCH PACKAGE

When it comes to welding aluminum parts robotically, arc starts and consistent wire feeding are crucial. AutoDrive® SA is a high-performance aluminum servo torch solution engineered to address the common problems with robotic aluminum welding – all to make the welding process easier and hassle-free. The system integrates with a robot and communicates directly with a Lincoln Electric® Power Wave® resulting in a best-in-class Aluminum solution.

POWER WAVE® STT® MODULE

Add STT® (Surface Tension Transfer®) process capability to any compatible Power Wave® S-Series power source to gain outstanding puddle control for critical sheet metal or pipe root pass welding. The compact STT® module seamlessly integrates with the power source using the high speed Lincoln Electric ArcLink® digital communications protocol.

- Exceptional Arc Control – Outstanding burnthrough control on thin metal or critical pipe welding.

- Ultimarc™ – In synergic STT® modes, it dynamically and simultaneously controls all heat input parameters together, including peak, background and tailout currents. The result is easy procedural setting for the operator.

- Modular Design – The module allows easy connection and fast digital communication with compatible S-Series Power Wave® power sources, Power Feed™ wire feeders, and compatible water coolers. Add STT® capability without having to purchase a second power source.

- Compact Footprint – The module is designed to securely connect directly below Lincoln S-Series Power Wave® models, without taking valuable floor space.

- Self-Protecting Circuits – The module will protect itself from the excessive transient voltages associated with highly inductive weld circuits.

POWER WAVE® ADVANCED MODULE

Expand Your Welding Capabilities

The Power Wave® Advanced Module increases flexibility by expanding your welding capabilities. The module has alternating current (AC) welding capability to run aluminum processes. With the module, you’ll have the ability to perform several welding processes with Pulsed Gas Metal Arc Welding (GMAW-P), Gas Tungsten Arc Welding (GTAW) and Surface Tension Transfer® (STT).

- The Power Wave Advanced Module – Provides multi-process reverse polarity (DC+), straight polarity (DC-), AC, high frequency TIG and STT functionality.

- Integrated Control Cables – Provides easy connection to compatible Power Wave models.

- Quick Lock Mounting System – Provides a way to safely secure the module to the power source.

- Ingress Protection (IP23) Safety – Provides use in outdoor applications.

- Protects against the entry of medium sized foreign bodies greater than 12 millimeters in diameter, along with spray water from any direction up to 60 degrees from the vertical.

- ArcLink® Digital Communications – Trades status and identification information while receiving high-speed, synchronized switching command from the power source.

- Intelligent Protection – Prevents potential damage caused by misconnection and voltage transients.

- Fan – Synchronizes operation with the host power source.

Technology

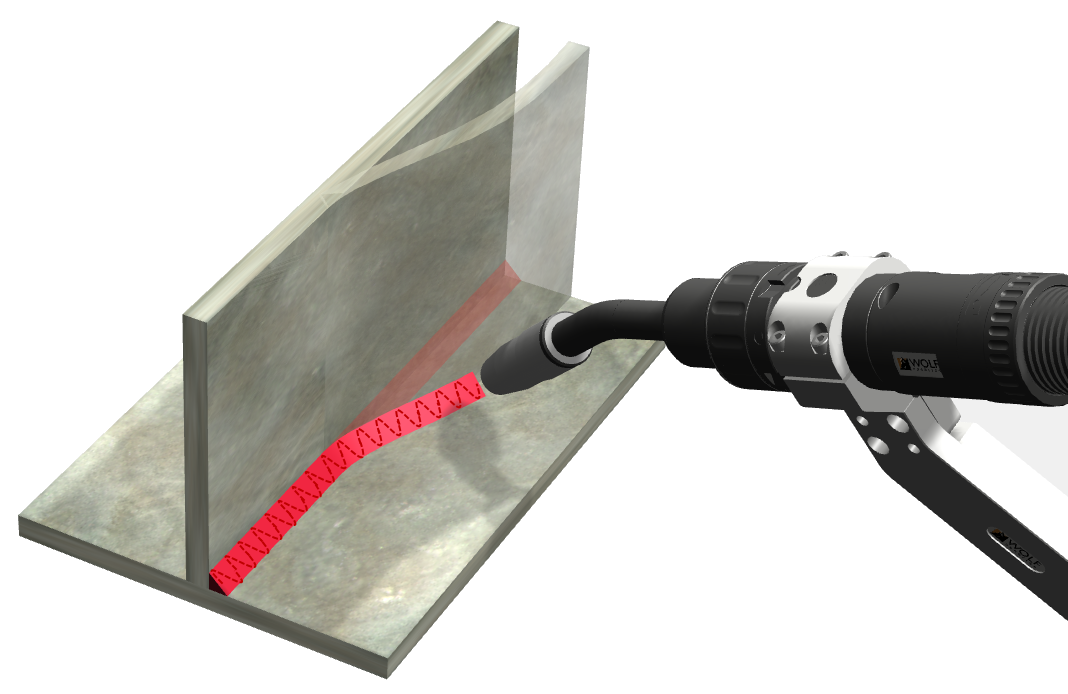

TOUCHSENSE

Wolf Robotics has developed a software solution that allows for in-production adjustments to be made to ensure accurate weld placement.

How TouchSense Works:

Voltage is applied to the wire or nozzle to perform a search and to automatically move the torch to the weld joint start point. Based on the search result the weld path is offset to match the real location of the joint.

TouchSense call also be used with camera or laser technology to detect part variances.

We highly recommend TouchSense in welding parts with any variance.

THRU-ARC TRACKING

With Thru-Arc Tracking the robot will automatically correct itself based on live measurements being made during the welding process to ensure the torch is centered within the weld joint.

Thru-Arc tracking is a very popular option, providing tracking in 3 directions; left, right and vertical.

Thru-Arc Tracking is highly recommended for any welding application with symmetric weld joints 1/8″ (3 mm) and larger.

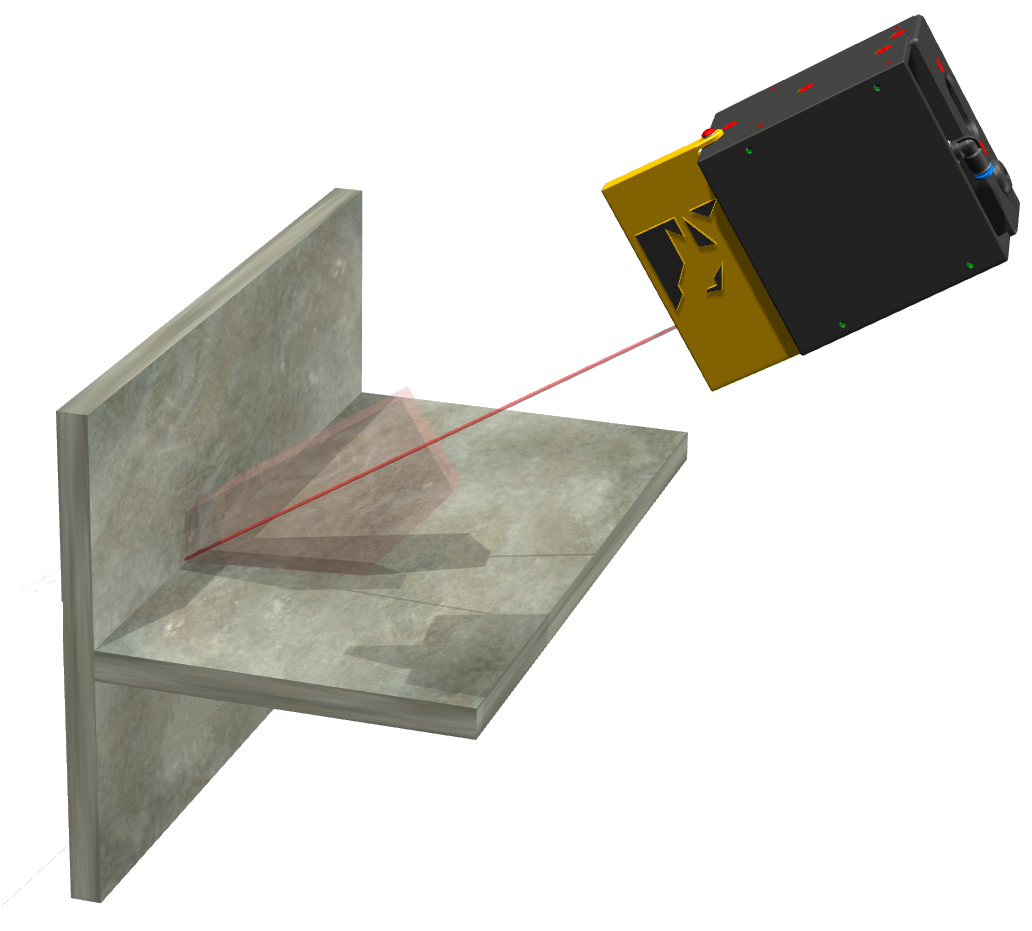

LASER SPOT SENSING

- Repeatable measurement of a single point

- Small, compact, easy-to-mount head

- Rugged head structure

Peripherals

TORCH MAINTENANCE STATION

The torch maintenance station is a true plug-and-play solution for robotic welding torch maintenance. Featuring a single-point connector system, the station comes equipped with catch tray covers on the reamer blade and wire cutting station for a cleaner, more efficient reaming cycle.

The anti-spatter injection unit for the station is a new pneumatic-based application that eliminates the need for a solenoid and allows for activation via the robot’s motion.

The protective covering around the injector improves coverage to the welding nozzle and collects more overspray.

Features and Benefits:

- Solenoids integrated into station stand for improved protection and easy access

- Single point connector for a true plug-and-play torch cleaning solution

- Optimized module stand height for simpler access and easier placement in the weld cell

- Anti-spatter Injector easily adjustable and able to be maintained tool-free

ROLL SHIELD RETRACTABLE SAFETY CURTAIN

The Roll Shield protects workers from harmful welding flash, heat, sparks and flying debris.

- Easy to use.

- Aids in containing process driven hazards.

SOLID PANEL FENCING

Solid panel fencing protects workers from harmful welding flash, heat, sparks and flying debris. ALSO AVAILABLE WITH WINDOWS.

STACK LIGHT STATUS DISPLAY

Attaching a stack light status display to a Fab-Pak system can make all the difference in worker safety.

FUME EXTRACTION & HOOD

The Lincoln Electric Prism exhaust hood is a modular system that manages fume extraction in your automation welding and cutting processes with cost-effective simplicity. The Prism exhaust hood’s modular design and extensive range of configurations enable you to customize your fume extraction system to fit your exact automation cell dimensions without sacrificing efficiency.