Software Solutions for Automation

WOLFARC

WolfArc™ enables users to activate different weld modes and configure the welds for use with an ABB® robot and Power Wave®. WolfArc provides real-time feedback on weld quality, increasing the overall quality of production.

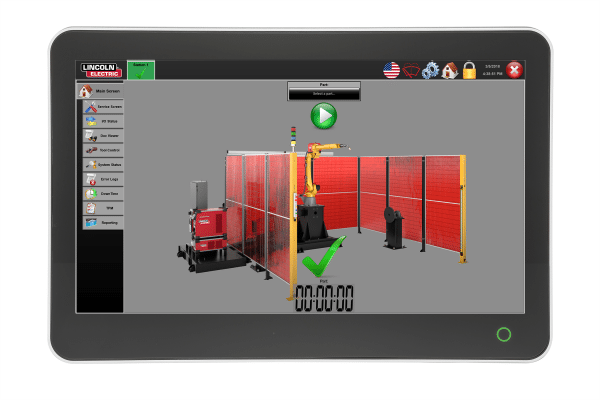

FAB-PAK CELL CONTROL

Fab-Pak® Cell Control is an easy-to-use, entry level, graphical user interface. The Fab-Pak cell control provides the operator of the Fab-Pak System control of normal production functions, robotic arc welding cell operation, and the welding process.

Fab-Pak Cell Control is available only on Fab-Pak pre-engineered welding systems.

Learn More

PLUS CELL CONTROL

Plus Cell Control is an easy-to-use, graphical user interface. The Plus Cell Control is intuitive, straightforward and provides the operator with the ability to control normal production functions, robotic arc welding cell operation, and the welding process. With Plus Cell Control, part production reports are included to help pinpoint areas of opportunity.

The Plus Cell Control provides a 21′ inch display with multi-touch capabilities.

Learn More

PREMIUM CELL CONTROL

Premium Cell Control is an easy-to-use, graphical user interface. The Premium Cell Control is intuitive, straightforward and provides the operator with the ability to control normal production functions, robotic arc welding cell operation, and the welding process. With Premium Cell Control, several reports are included to help provide production insights and to help ensure proper maintenance.

The Premium Cell Control provides a 21′ inch display with multi-touch capabilities.

Learn More

COMPUTER AIDED ROBOTIC – WELDING (CAR-W)

Computer Aided Robotic Welding (CAR–W™) is the latest in automated robotic path planning software from Wolf Robotics. Following the same principles as CAD/CAM software for CNC machining, robotic welding programs are automatically generated from CAD models. This CAD/CAR exchange virtually eliminates manual and off-line programming, and vastly reduces required training.

Learn More

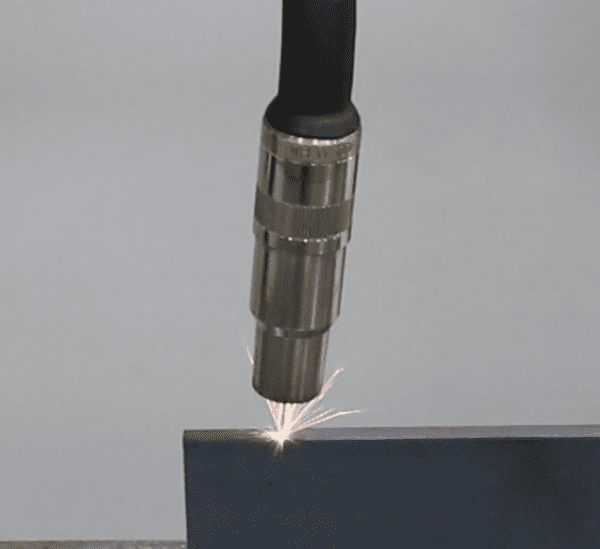

Wolf TouchSense

Wolf Robotics has developed a software solution that allows for in-production adjustments to be made to ensure accurate weld placement.

How TouchSense Works:

Voltage is applied to the wire or nozzle to perform a search and to automatically move the torch to the weld joint start point. Based on the search result the weld path is offset to match the real location of the joint.

TouchSense call also be used with camera or laser technology to detect part variances.

We highly recommend Wolf TouchSense in welding parts with any variance.

Wolf Thru-Arc Tracking

With Thru-Arc Tracking the robot will automatically correct itself based on live measurements being made during the welding process to ensure the torch is centered within the weld joint.

Thru-Arc tracking is a very popular option, providing tracking in 3 directions; left, right and vertical.

Wolf Thru-Arc Tracking is highly recommended for any welding application with symmetric weld joints 1/8″ (3 mm) and larger.

![]()

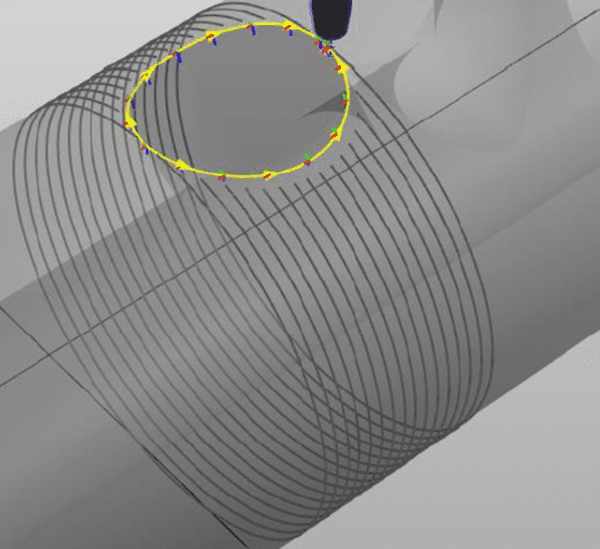

WolfClad

Wolf Robotics has developed cladding software that works with a variety of surfaces including cylindrical, conical, spherical, planar, and even those with varying cross-sections.

How WolfClad Works:

WolfClad automatically programs around holes, cutouts, or other intersecting features. You can even define weave shapes, bead overlap and multi-pass overlay.

WolfClad is recommended for all robotic cladding systems.

Stitch Weld for WolfArc

Wolf Robotics Stitch Weld software solution takes the tedious, time-consuming work out of programming the robot for stitch welds.

How Stitch Weld for WolfArc Works:

Rather than program every start and finish of each weld, with Stitch Weld for WolfArc all you need to do is program one start, how long you want the welds and how far apart you want the welds

Stitch Weld for WolfArc is highly recommended for any robotic stitch weld applications.

Advanced Multi-Pass Software

Wolf Robotics Advanced Multi-Pass software solution allows you the ability to easily program stacked welds.

Based off the first pass and weld size, Advanced Multi-Pass software will offset subsequent weld passes. You’ll save time and increase productivity by not having to program each individual weld pass.

Advanced Mult-Pass software is highly recommended for large joints requiring muli-pass welds.