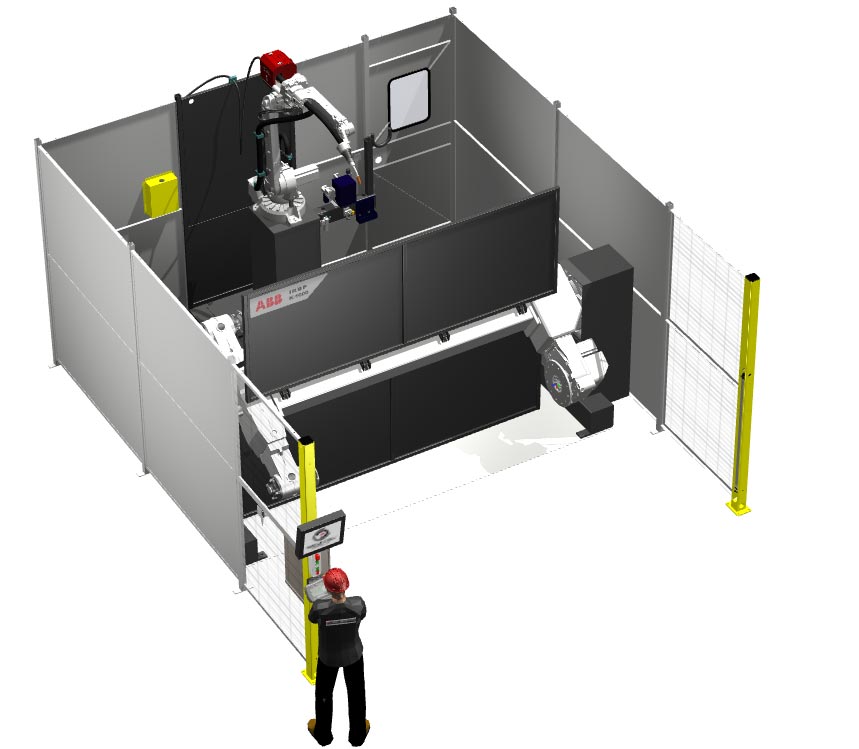

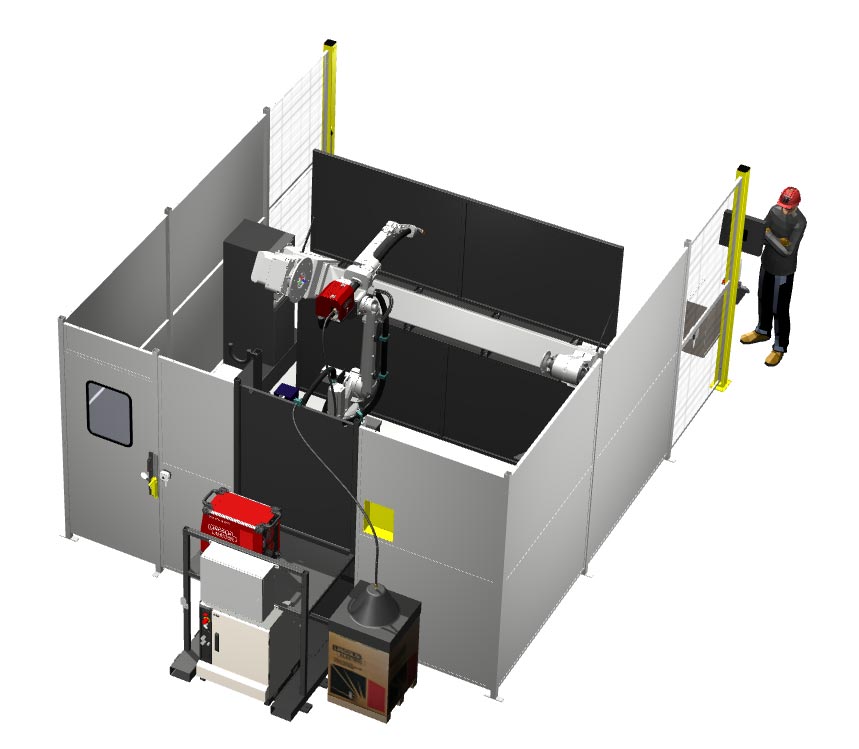

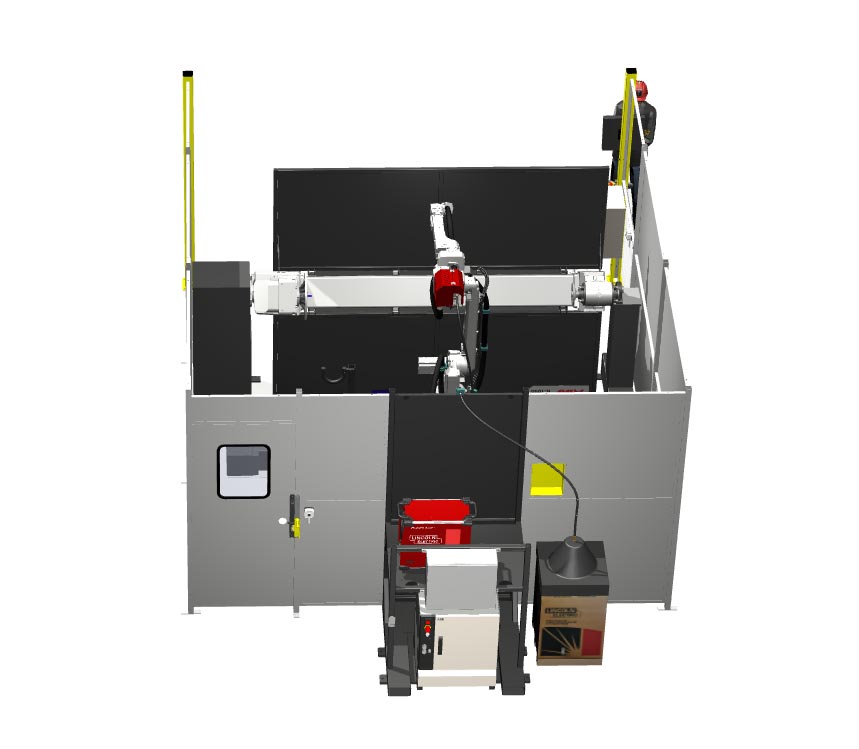

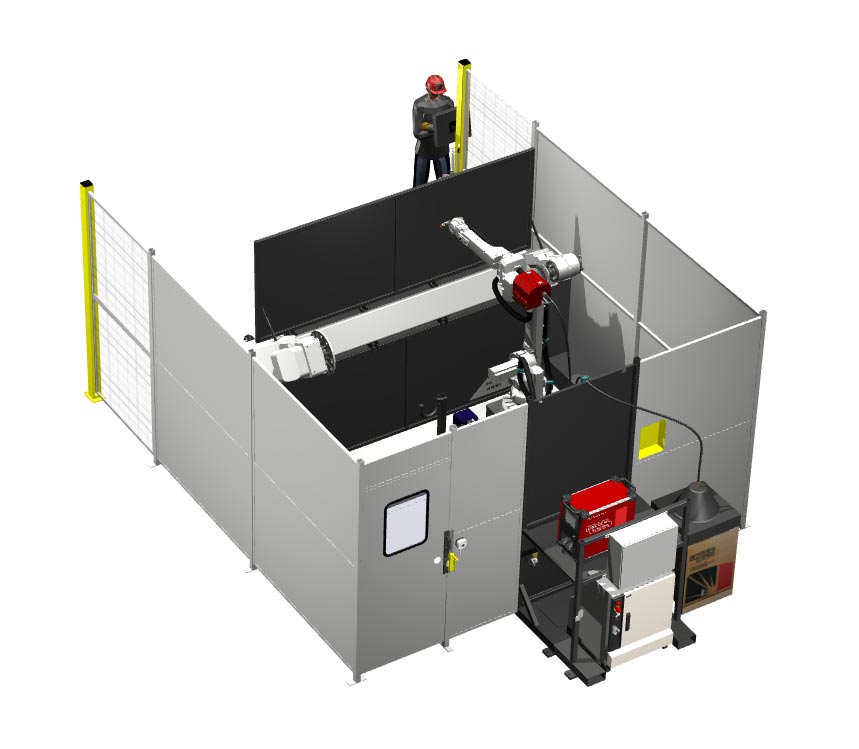

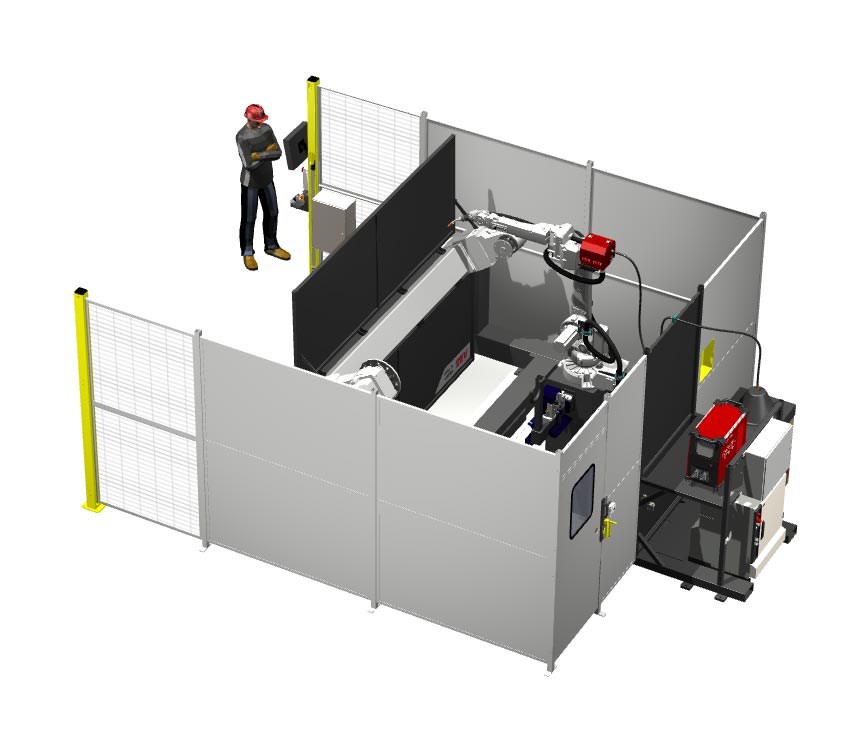

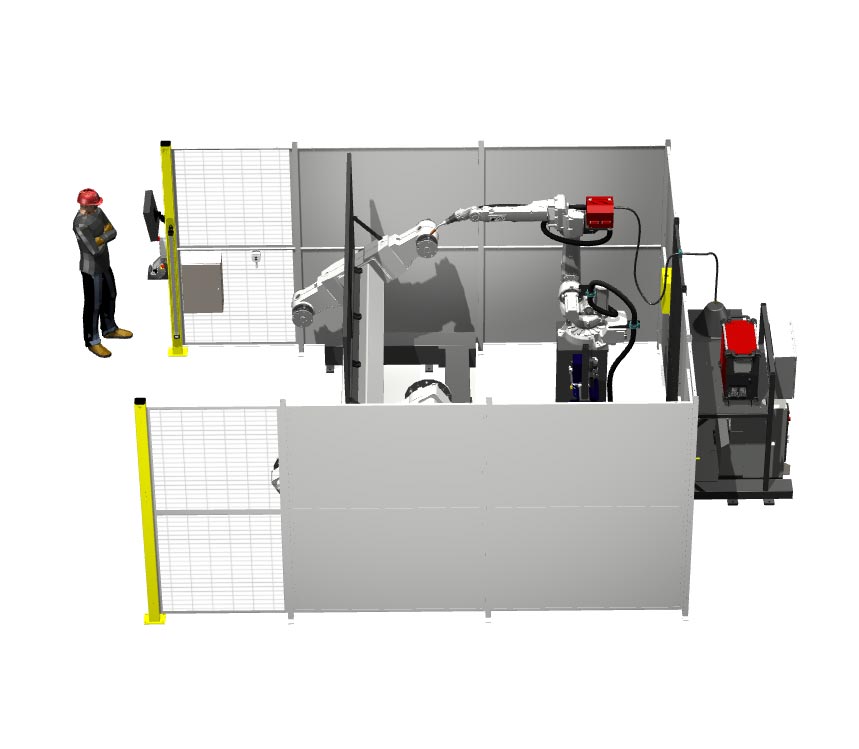

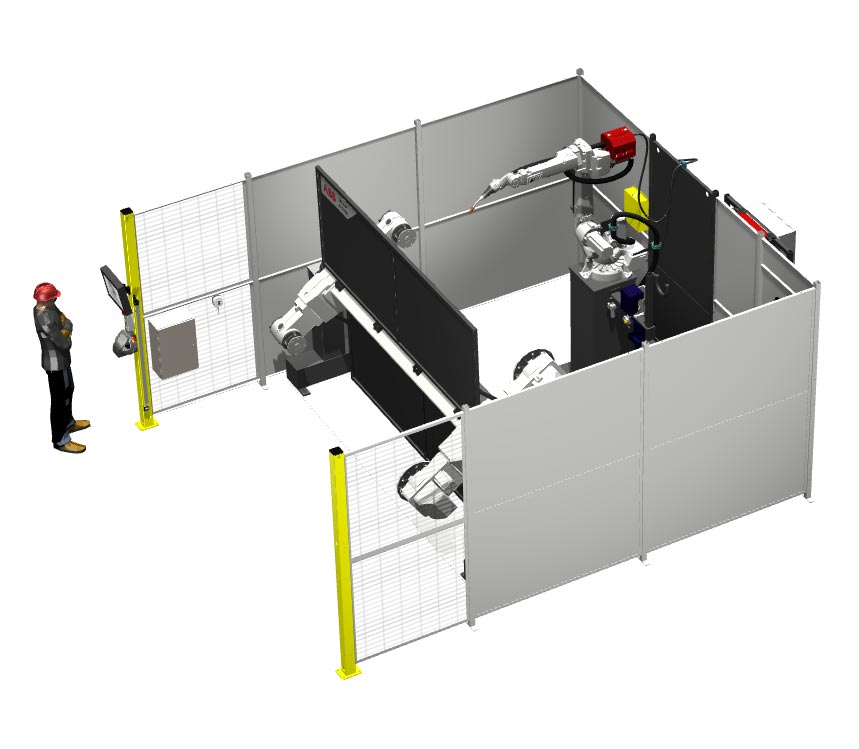

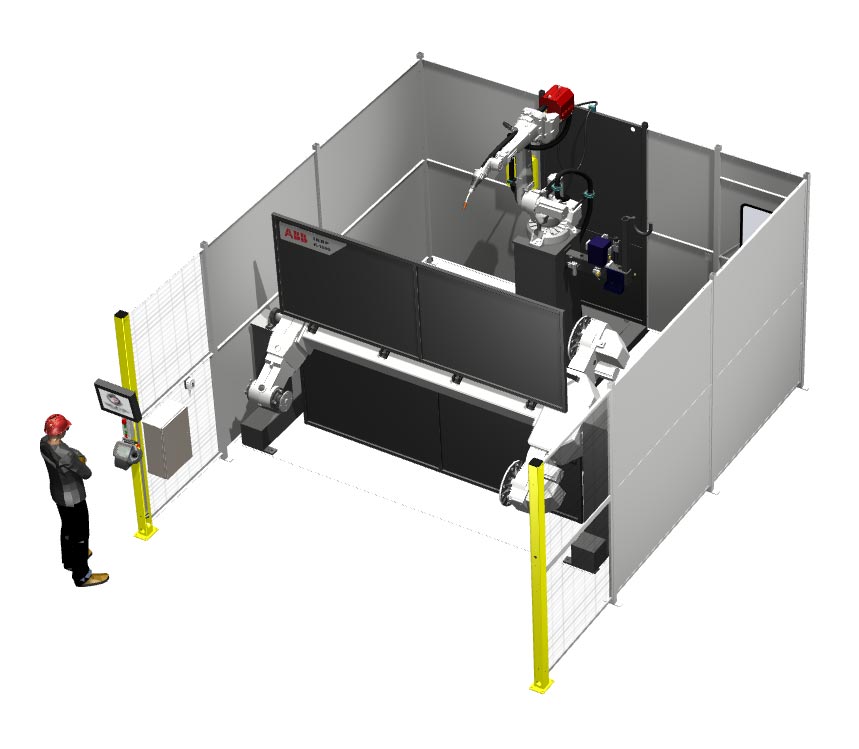

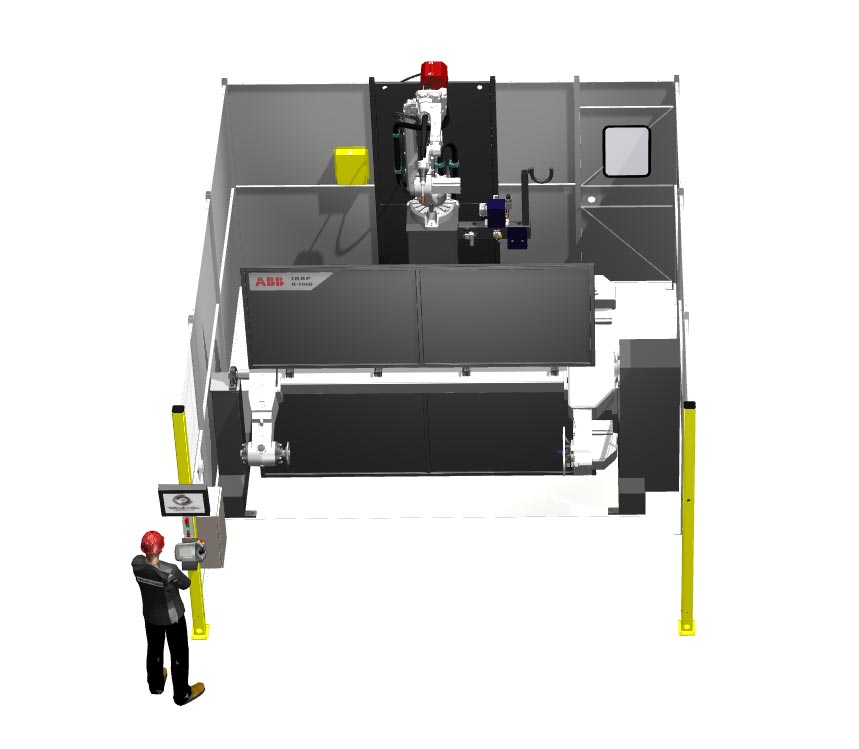

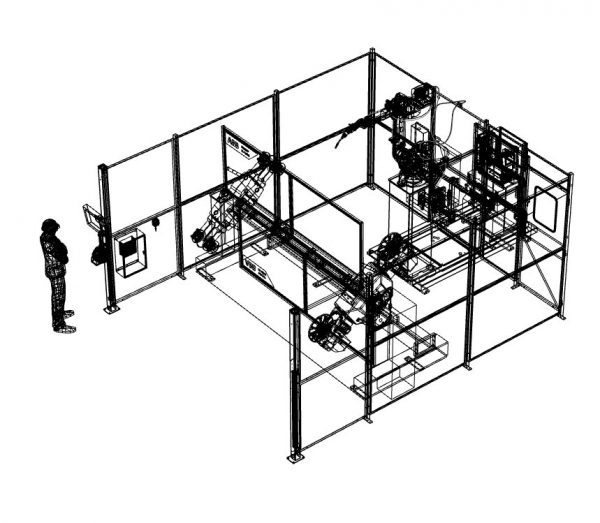

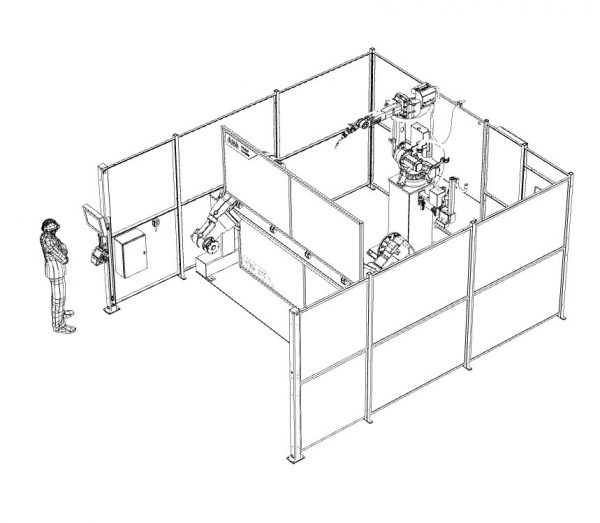

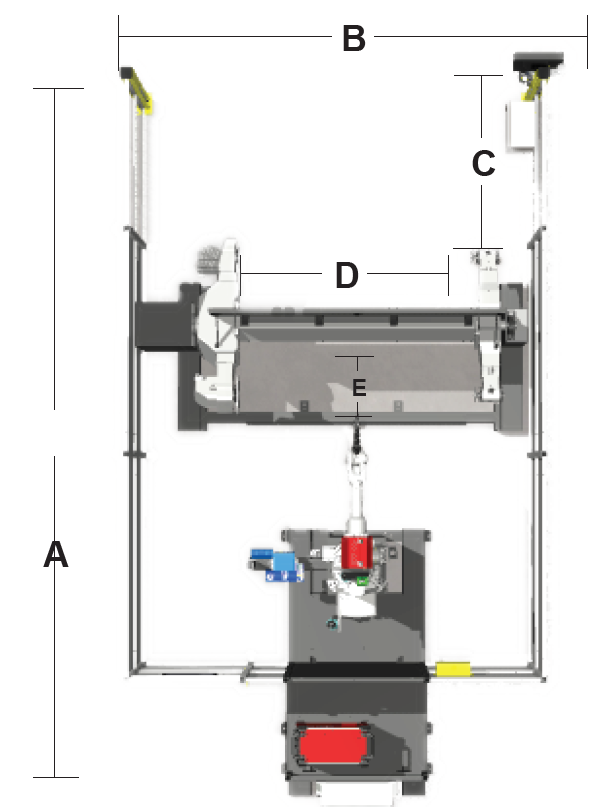

Ferris Wheel

Ready-to-Weld

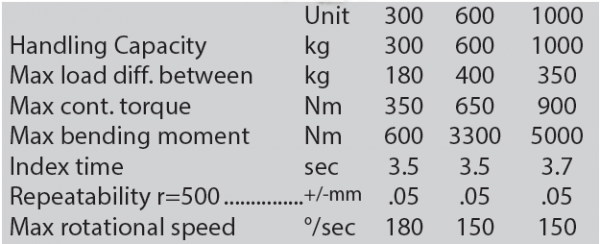

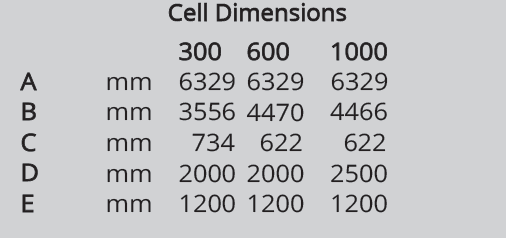

300/600/1000

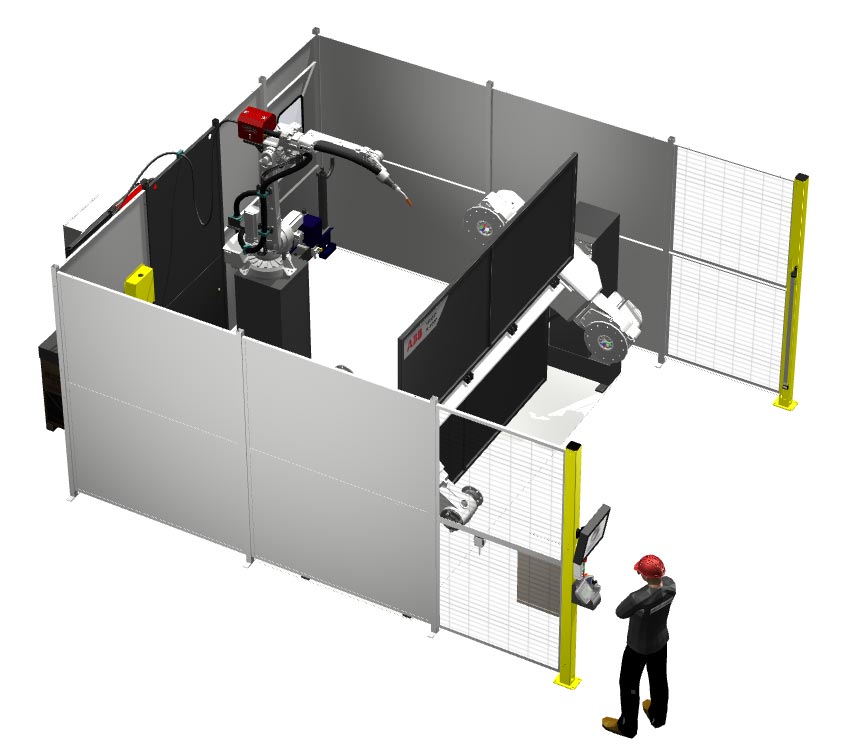

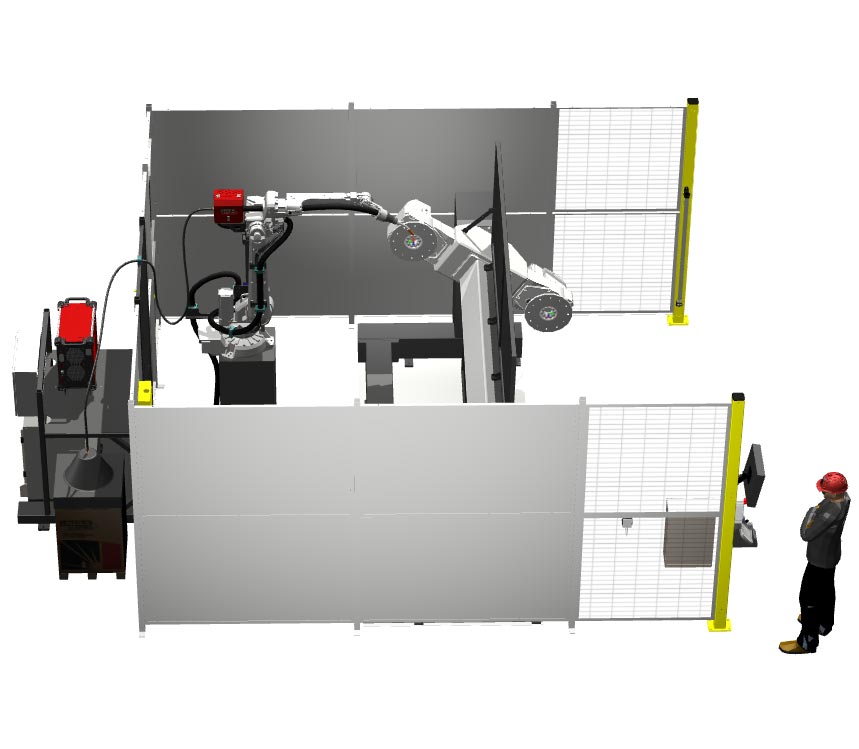

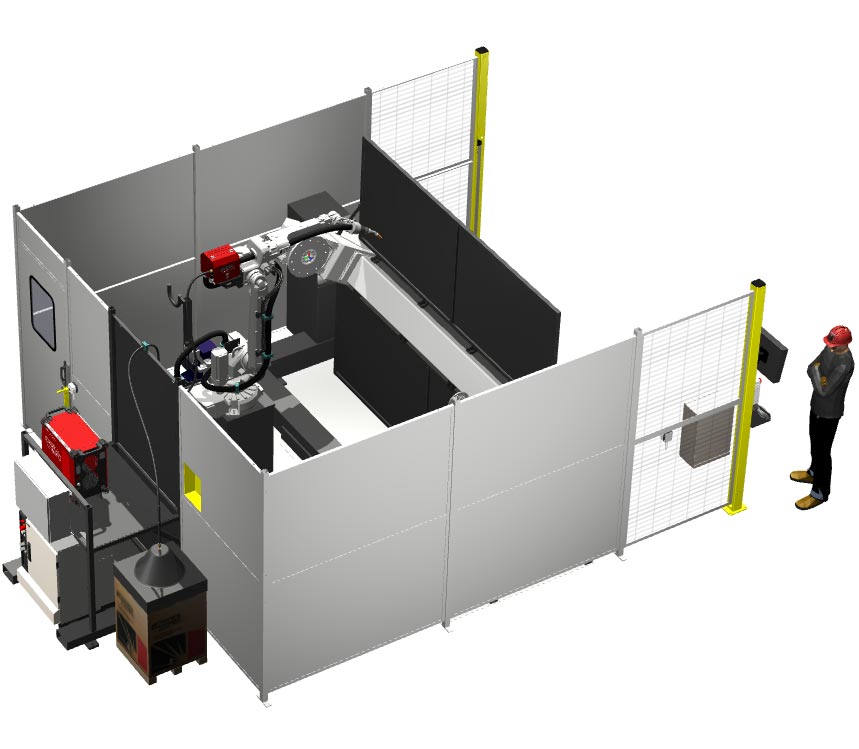

CONFIGURATIONS

The pre-engineered Ferris Wheel robotic system is an arc welding solution delivered ready-to-weld.

The Ferris Wheel system is a cost-effective way to automate your fabrication operations and improve productivity, efficiency, and profitability through advanced error handling, production monitoring, and self diagnostics.

Download BrochureBenefits

- Short delivery and set-up times

- Low investment

- Less downtime with improved error handling

- Improved safety features

- Portability

- Small footprint

- High quality production through production monitoring and self-diagnostics

- Offline programming and tooling design capabilities

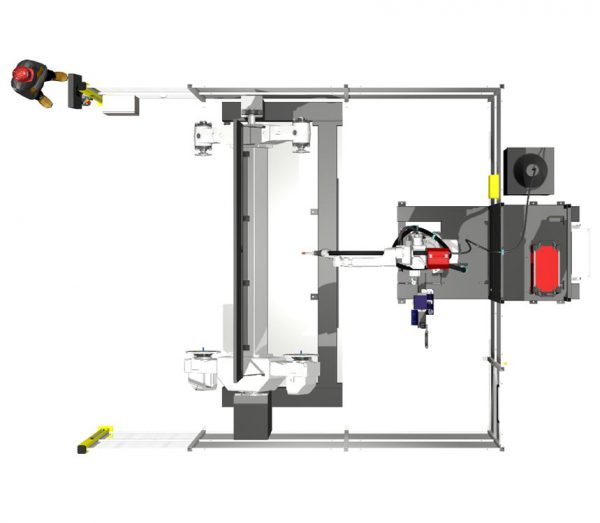

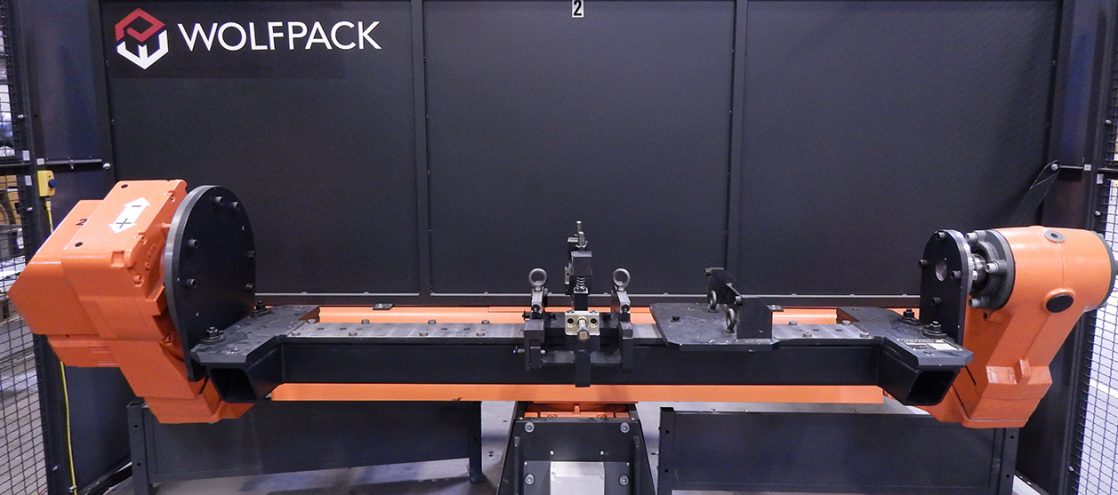

- Assorted positioners & capacities

- Robot CMM capabilities

Specifications

Pre-Engineered Robotic Welding System Highlights

Optional Fab-Pak Cell Co

Many options to customize robot cell for your specific needs

Custom tooling ready

Quick delivery and easy set-up