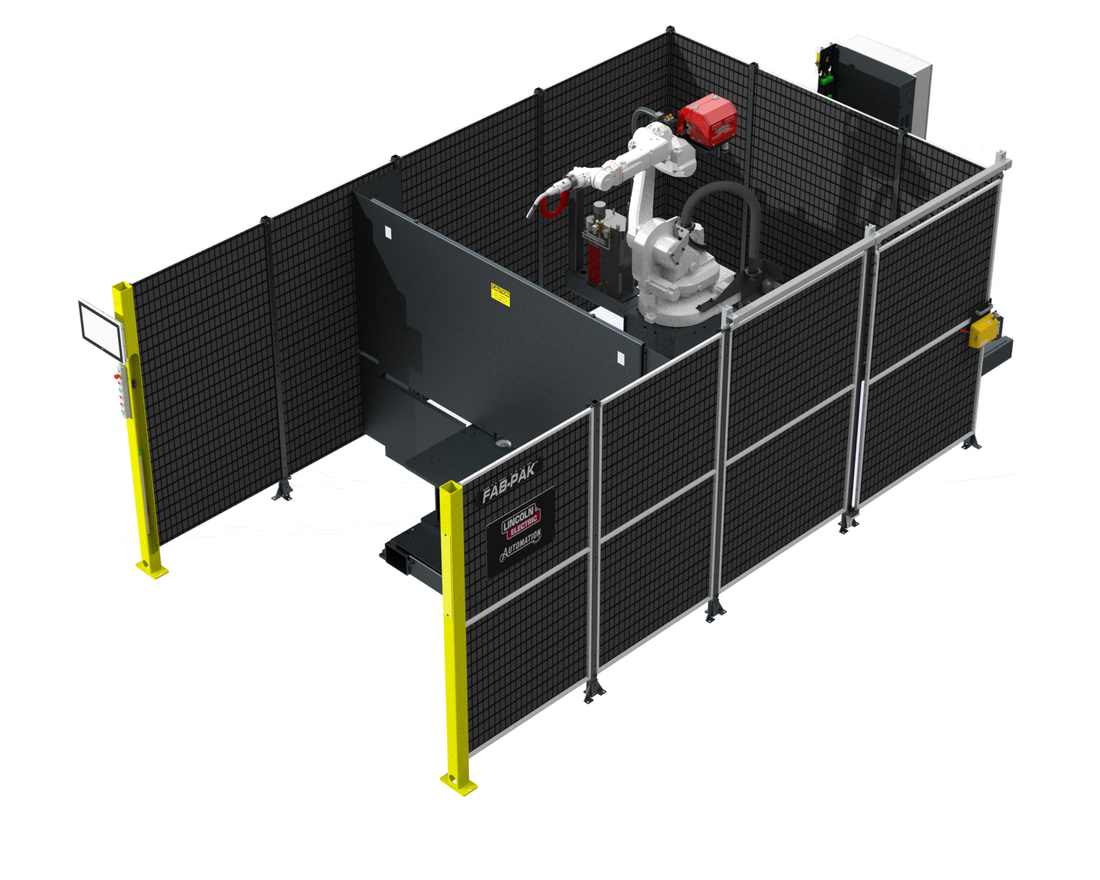

Fab-Pak ABB XFT

Rotating Turntable System, ABB

Ready-to-Weld Automation from the Welding Experts®

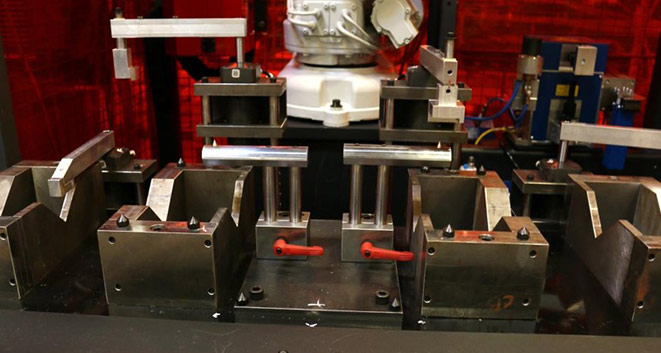

Fab-Pak XFT with ABB Robot

The pre-engineered Fab-Pak® XFT is a rotating turntable system for robotic arc welding. The turntable can rotate 180 degrees. The Fab-Pak XFT has a single load/unload area and two independent work zones. This system is a great solution for small to medium sized parts.

Fab-Pak XFT with ABB robot arc welding system is a cost-effective way to automate your fabrication operations and improve productivity, efficiency, and profitability through advanced error handling, production monitoring, and self-diagnostics.

Increase Production, Improve Weld Quality and Address Labor Shortages

Our affordable, pre-engineered ABB Fab-Pak Arc Welding Systems help manufactures remain competitive by speeding up production, addressing the shortage of skilled welders, reducing labor costs and improving the consistency and quality of welds.

Benefits

- Short delivery and set-up times

- Low investment

- Less downtime with improved error handling

- Ease of use

- Improved safety

- Portability

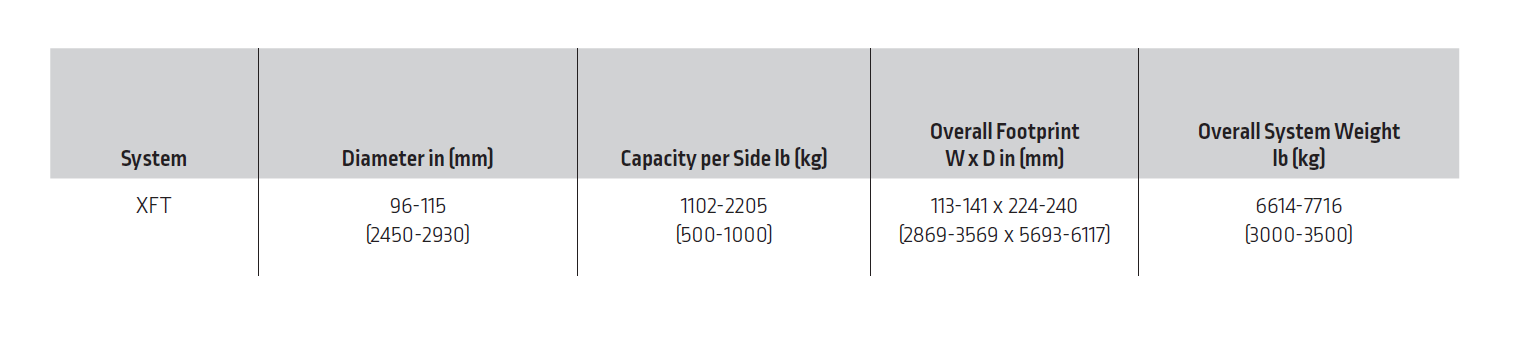

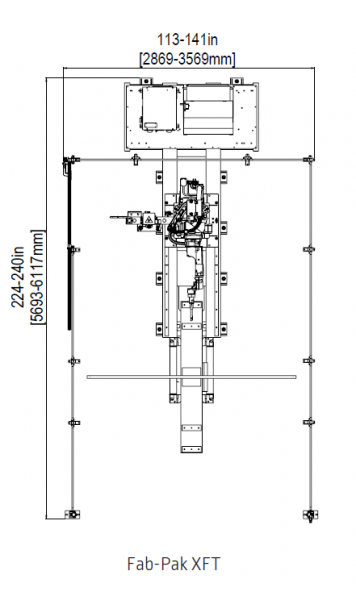

- Small footprint

- Increase production and create a competitive advantage

- Improved weld quality

- Decrease scrap and rework

Standard Features

- Magnum® Pro Robotic Torch

- ABB Welding Robot

- Autodrive® Wire Feeder

- Push Button Control

- Power Wave® Power Source

- Wire Mesh Fencing with Weld Curtain

- Full Operator Safety Package

- Headstock Positioner

Optional Features

- Solid Sheet Metal Panels

- Fume Extraction Equipment

- Tooling

- Robotic Torch Cleaning Station

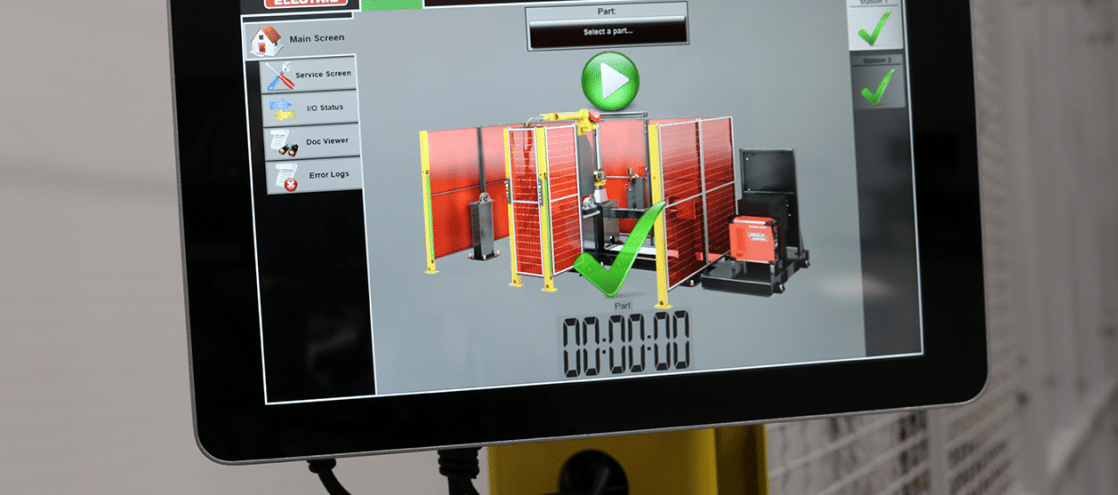

- Fab-Pak™ Cell Control

- Power Distribution

- Zero Friction Wire Delivery

- Wire Detect Sensors

- Installation

Fab-Pak Pre-Engineered Robotic Welding System Highlights

Optional Fab-Pak Cell Control, an easy-to-use graphical user interface

Custom tooling ready

Many options to customize robot cell for your specific needs

Quick delivery and easy set-up