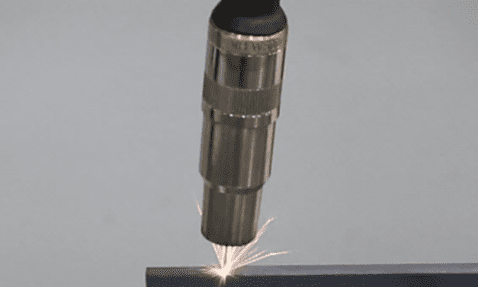

As the coronavirus (COVID-19) crisis accelerates, many medical equipment manufacturers are looking to automation to increase production. Lincoln Electric’s TopTig• technology is providing the solution these manufactures need to meet the surge in demand. “As the pandemic evolves, we’re seeing manufacturers explore automation options to ramp up production. In the past, robotic TIG welding was…

Read MoreWhat's Happening at Wolf Robotics

Need automation? Don’t let cash flow stand in the way. By financing your automation system, you can make it a reality TODAY. Lincoln Electric Automation has partnered with ENGS Commercial Finance, a leader in financing for the fabrication industry. For over 65 years, Engs has provided a wide range of lease and financing options to…

Read MoreThe latest technology will give Renton Technical College welding and machining students an advantage in the workforce. The welding shop is now home to a cutting-edge Fanuc robotic welder. The machine (an ARC mate 100ic/12 Thro-arm Robotic package with GMAW welder provided by WOLF Robotics, a Lincoln Electric company) was made possible through a major…

Read MoreThe robotic weld cell has multiple benefits for next generation combat vehicles: the quality and performance of weldments is higher, which results in better vehicle protection; and the automation reduces welding time by nearly 80 percent, which will help the Army meet its critical delivery requirements. Read the complete article here… https://www.army.mil/article/230801/army_introduces_weld_automation_for_next_generation_combat_vehicles?fbclid=IwAR20j1cE62V5qOd4QJHCINtkjabrRzVjmbsrPbRGAYKAAkAdoHMKost34kE

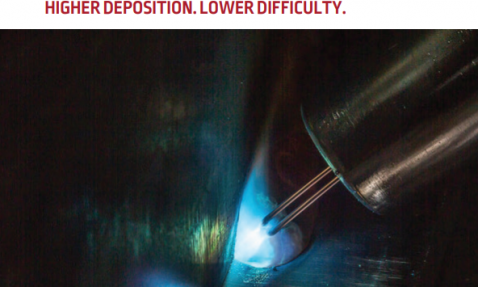

Read MoreHeavy Fabrication Solution We are excited to introduce HyperFill™, a patent pending twin-wire MIG solution that revolutionizes high deposition welding. Developed for both semi-automatic or robotic applications, HyperFill increases the usable deposition rate compared to traditional single wire MIG while delivering excellent weld quality and puddle stability. HyperFill Benefits: Maximize productivity – Increases deposition rates…

Read MorePerfect part fit-up doesn’t always happen and some weld seams are simply not repeatable. That’s ok…we have a solution. For the robot to weld these seams, which are out of tolerance, Wolf Robotics equips the robotic welding with Wolf TouchSense, a tactile sensing capability. Wolf TouchSense works by applying a safe voltage either to the…

Read MoreIf you’re working with the right robotic integrator the relationship between you and your integrator should be a partnership where the integrator works with you closely from start to finish to deliver the right solution. Your integrator should be a trusted adviser, someone you can rely upon and someone you know will get the job…

Read MoreAt Wolf Robotics, we often hear from many of our customers regarding their pain points such as: how they constantly have to adjust due to the lack of skilled welders the need to improve weld quality and consistency having to reduce costs to remain competitive the need to speed up production These industry realities are…

Read MoreNate is an application engineer intern (started January, 2015), who just graduated from CSU in Mechanical Engineering. What do you enjoy most about working at Wolf Robotics? “It’s a rare internship experience that allows you to experience multiple facets (i.e. starting on the floor and moving to positions upstairs) of the professional engineering world.” Working…

Read MoreWhen will additive manufacturing make sense for the job shop? Emerging technologies are printing large metal parts now Additive manufacturing (AM) is still young. Proponents continue to improve the processes, expand workable materials, and develop new deposition techniques. All have, or will have, the ability to enhance and complement traditional manufacturing processes well beyond the…

Read More