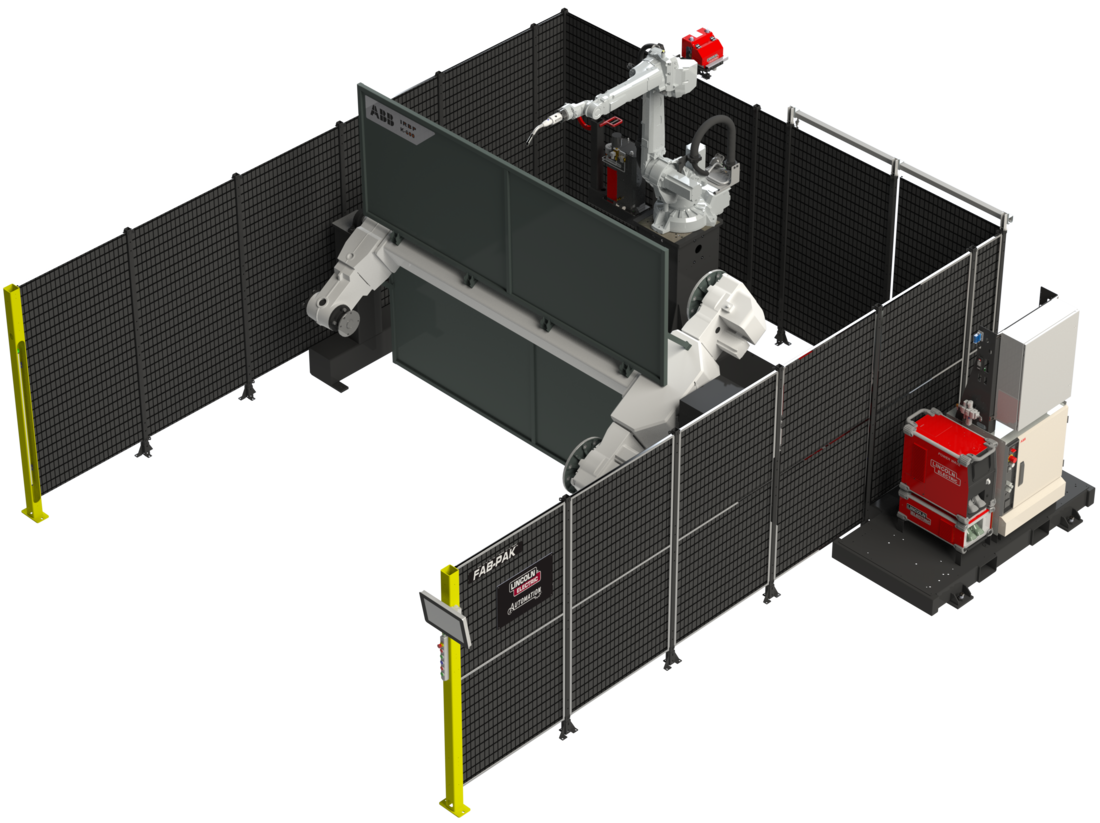

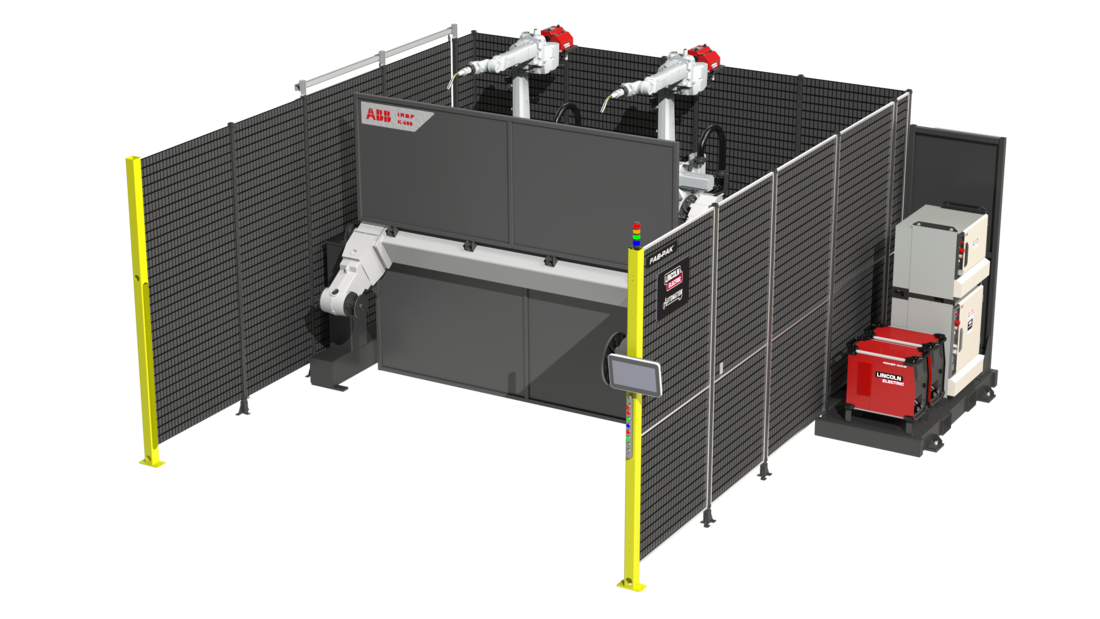

Fab-Pak ABB FW

FERRIS WHEEL SYSTEM, ABB

Ready-to-Weld Automation from the Welding Experts®

Fab-Pak FW with ABB Robot

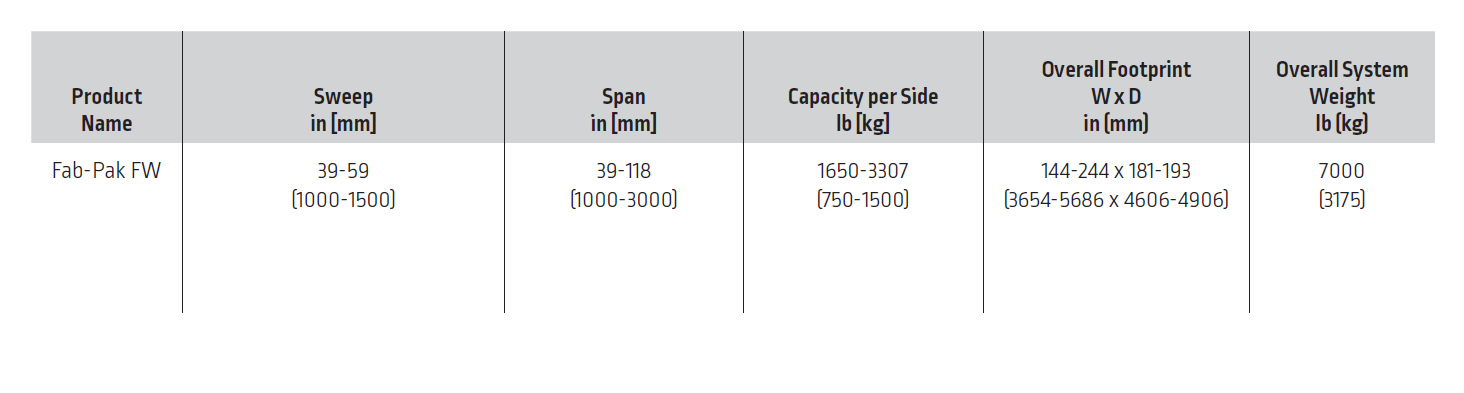

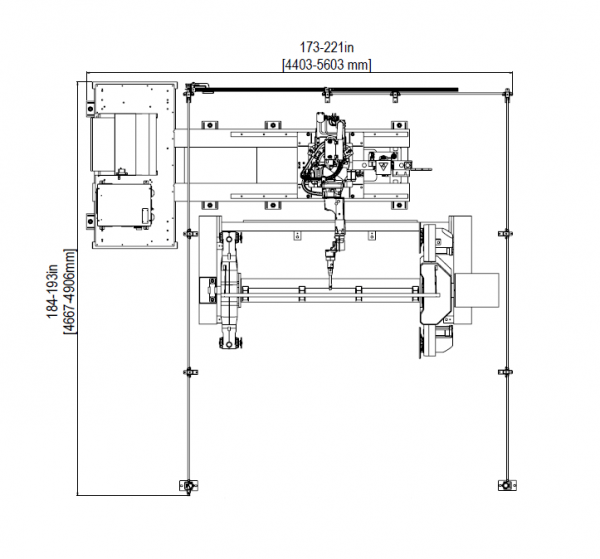

The pre-engineered Fab-Pak® ferris wheel robotic system is an arc welding solution delivered ready-to-weld. The ferris wheel is a two zone system that rotates 180 degrees. It has a single load/unload point. Each zone contains a headstock for easy reorientation of parts and is a great solution for large sized parts.

Fab-Pak FW with ABB robot arc welding system is a cost-effective way to automate your fabrication operations and improve productivity, efficiency, and profitability through advanced error handling, production monitoring, and self diagnostics.

Increase Production, Improve Weld Quality and Address Labor Shortages

Our affordable, pre-engineered ABB Fab-Pak Arc Welding Systems help manufactures remain competitive by speeding up production, addressing the shortage of skilled welders, reducing labor costs and improving the consistency and quality of welds.

Benefits

- Short delivery and set-up times

- Low investment

- Less downtime with improved error handling

- Ease of use

- Improved safety

- Portability

- Small footprint

- Increase production and create a competitive advantage

- Improved weld quality

- Decrease scrap and rework

Standard Features

- Magnum® Pro Robotic Torch

- ABB Welding Robot

- Autodrive® Wire Feeder

- Push Button Control

- Power Wave® Power Source

- Wire Mesh Fencing with Weld Curtain

- Full Operator Safety Package

- Headstock Positioner

Optional Features

- Solid Sheet Metal Panels

- Fume Extraction Equipment

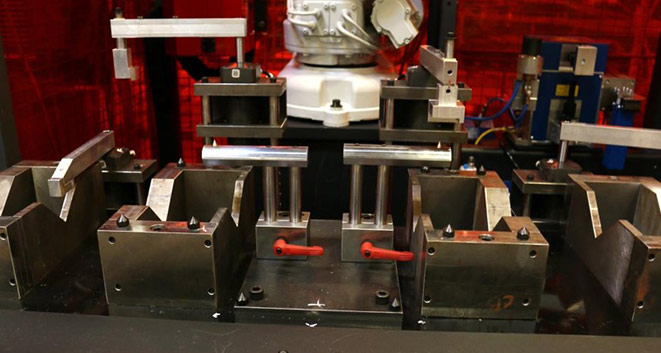

- Tooling

- Robotic Torch Cleaning Station

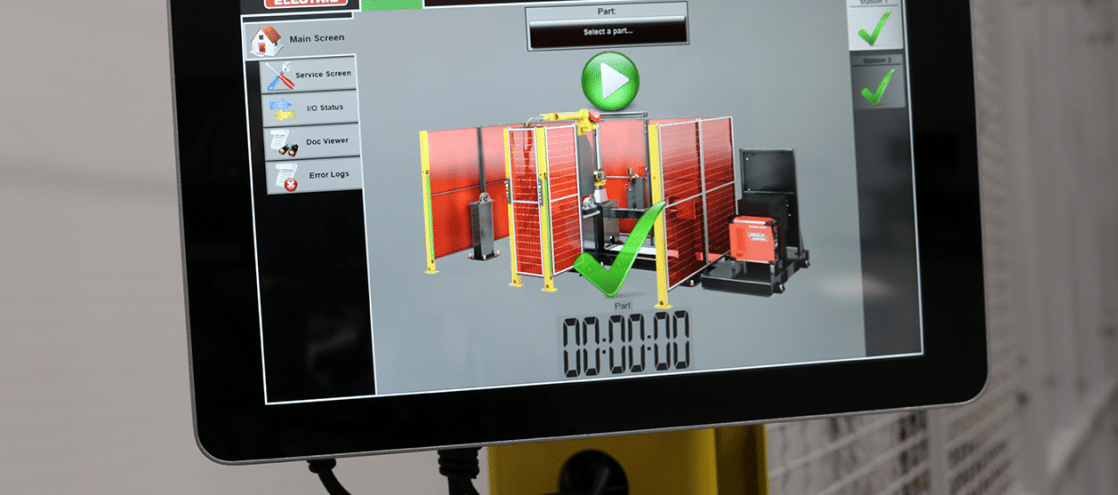

- Fab-Pak™ Cell Control

- Power Distribution

- Zero Friction Wire Delivery

- Wire Detect Sensors

- Installation

Fab-Pak Pre-Engineered Robotic Welding System Highlights

Optional Fab-Pak Cell Control, an easy-to-use graphical user interface

Custom tooling ready

Many options to customize robot cell for your specific needs

Quick delivery and easy set-up