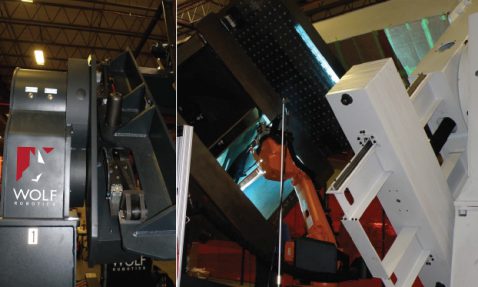

Industrial Fixtures (Tooling)

“Robotic welding systems can vastly improve productivity and increase quality. However, the level of efficiency of automation depends upon the thoughtful design of the tooling (fixturing) and meticulous manufacturing of the fixture. We do both.”

SmartDock – A Flexible Tooling Solution

Single Point Load System

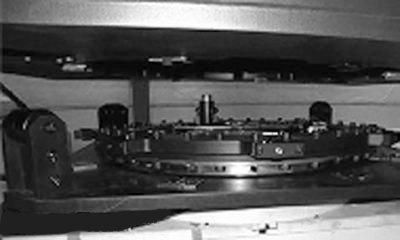

The SmartDock™ single point flexible tooling system is a simplified, low profile and robust means of interchanging tooling fixtures on your robotic welding positioner. This easy to use, safe, and secure system allows for precise locating of new fixture layouts.

How it works…

The SmartDock system consists of 3 parts working in union to allow for maximum manipulation and maneuverability.

- The system starts with the fixture plate, also known as the SmartGrid™. The SmartGrid fixture is a large plate comprised of 1,080 threaded holes to allow for multiple positioning capabilities.

- Next, a proprietary clamp, the SmartClamp™, is strategically placed around the SmartGrid plate. The threaded holes on the SmartGrid plate allow for the SmartClamp clamp to be positioned anywhere necessary on the SmartGrid plate. Once positioned each SmartClamp clamp is calibrated to exert the exact amount of pressure necessary to hold the piece safely and securely onto the SmartGrid plate. The SmartClamp clamp provides a visual gauge that displays the rated load and amount of pressure exerted. Once an object has been securely fastened to the SmartGrid plate, with the SmartClamp clamp, it is placed on top of the third piece of the system called the SmartDock.

- The SmartDock is a rotating bezel that allows the object to rotate a full 360 degrees. When these three parts come together with your Wolf Robotics positioner a single weldment can be positioned in a virtually infinite amount of ways. The SmartDock flexible tooling system is the optimum solution for providing the maximum amount of maneuverability when positioning your parts. The system is completely customizable, and can scale to fit your part’s requirements. With an enhanced ability to bare high load capacities, the SmartDock system can easily move and manipulate parts in a safe and secure manner.

Product Highlights

- High load capacities scalable to your needs

- Rotary activated axial clamping using rolling contact for minimal wear

- Simple design for low maintenance and easy loading/ unloading

- Replaceable wear surfaces for easy servicing

- Low profile grid plate covers and protects moving parts while providing full surface access for mounting/ clamping weldments

- Safe, robust design transfers load to main slew ring

Benefits of Using a SmartDock System

- Better access for welding (less clamp interference)

- Ability to accommodate a variety of parts and sizes in one fixture

- Reduce part changeover time

- Increase safety, productivity, and quality

Implementation

Depending on required clamping force, the SmartDock system is available in electrical, hydraulic, or air actuated configurations The SmartGrid is a precision component that can be quickly interchanged. The robot will recalibrate to the layout by sensing 3 points to determine position.

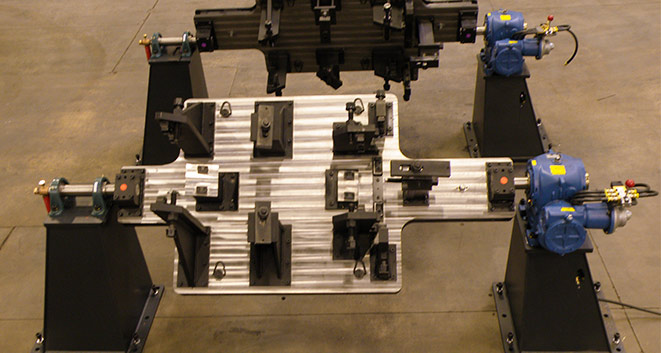

Also available in a Dual Load System for Headstock Tailstock:

Wolf Robotics created the dual-point SmartDock load system to handle longer parts. The Dual Load System has all the features and benefits of SmartDock’s Single Point System.

Custom Fixtures & Tools

Fixturing or tooling is an important part of any automated system. In fact, the right customized robotic fixture can also greatly improve the efficiency and productivity of all welding operations.

Wolf Robotics tooling engineers are experts in developing quality fixtures for every application and component that requires robotic welding. From automated systems to pneumatic or hydraulic requirements, Wolf has the experience and know-how to provide a product that’s capable of handling the most complicated and critical design elements. Our personnel will work with you to provide a solution that’s designed to your satisfaction and requirements.

Benefits of Wolf Robotics Custom Tooling:

- Enables repeatable weld quality

- Better access for welding (less clamp force interference)

- Ability to accommodate a variety of parts and sizes in one fixture

- Reduced part changeover time

- Increased productivity capacity

- Improved safety

- Greater part dependability

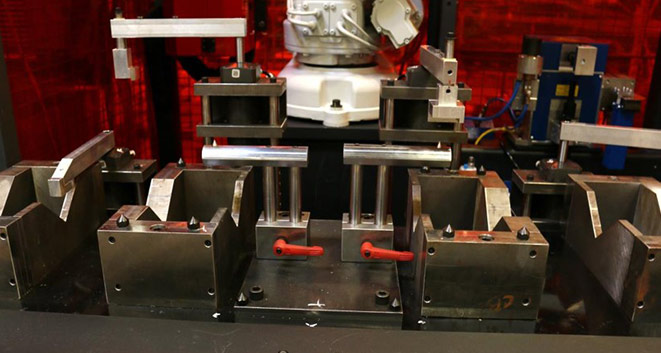

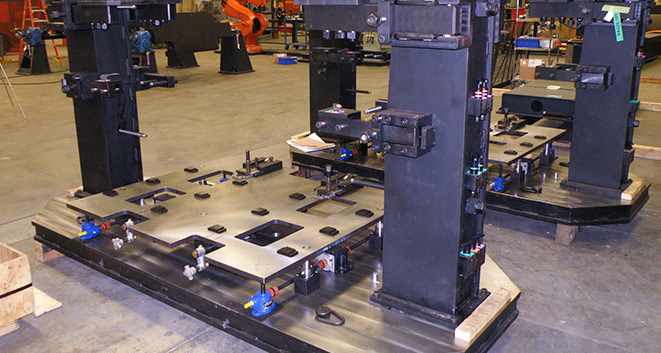

Custom Fixture Examples & Specifications:

- Weldment capacity 38,000 to 68,000 lbs.

- Adaptable to 15+ configurations

- Completely captures the weldment with minimal shifting during rotation

- Easily loaded/unloaded with safety prevention of accidental release.

Primary Uses:

- Tack welding

- Robotic welding

- Manual welding

- Assembly

- Machining